Flywheel Dynamometer

In an effort to really understand brushless motor and speed controller power curves, I wanted to build my own dynamometer. I'd read about using a flywheel as an inertial load. If you measure voltage and current into the motor (+ESC) you have electrical power into the system at each measurement time. If you calculate or measure the moment of inertia of a flywheel, and measure its speed and acceleration as the motor spins it up, you can calculate the power required to generate the torque that causes the acceleration. Power out/Power in= Efficiency. With one spin up and granular enough measurement intervals, you can map the efficiency of the motor at every RPM with a single run.

It sounds so simple, doesn't it?

Somehow the quality of data I wanted made the challenge much bigger than expected. I wanted a curve with hundreds of accurate data points to have confidence in the results. The flywheel MOI, top speed and motor power meant that i’d only have around 5 seconds from 0 to full speed to collect this data for the power range i was interested in.

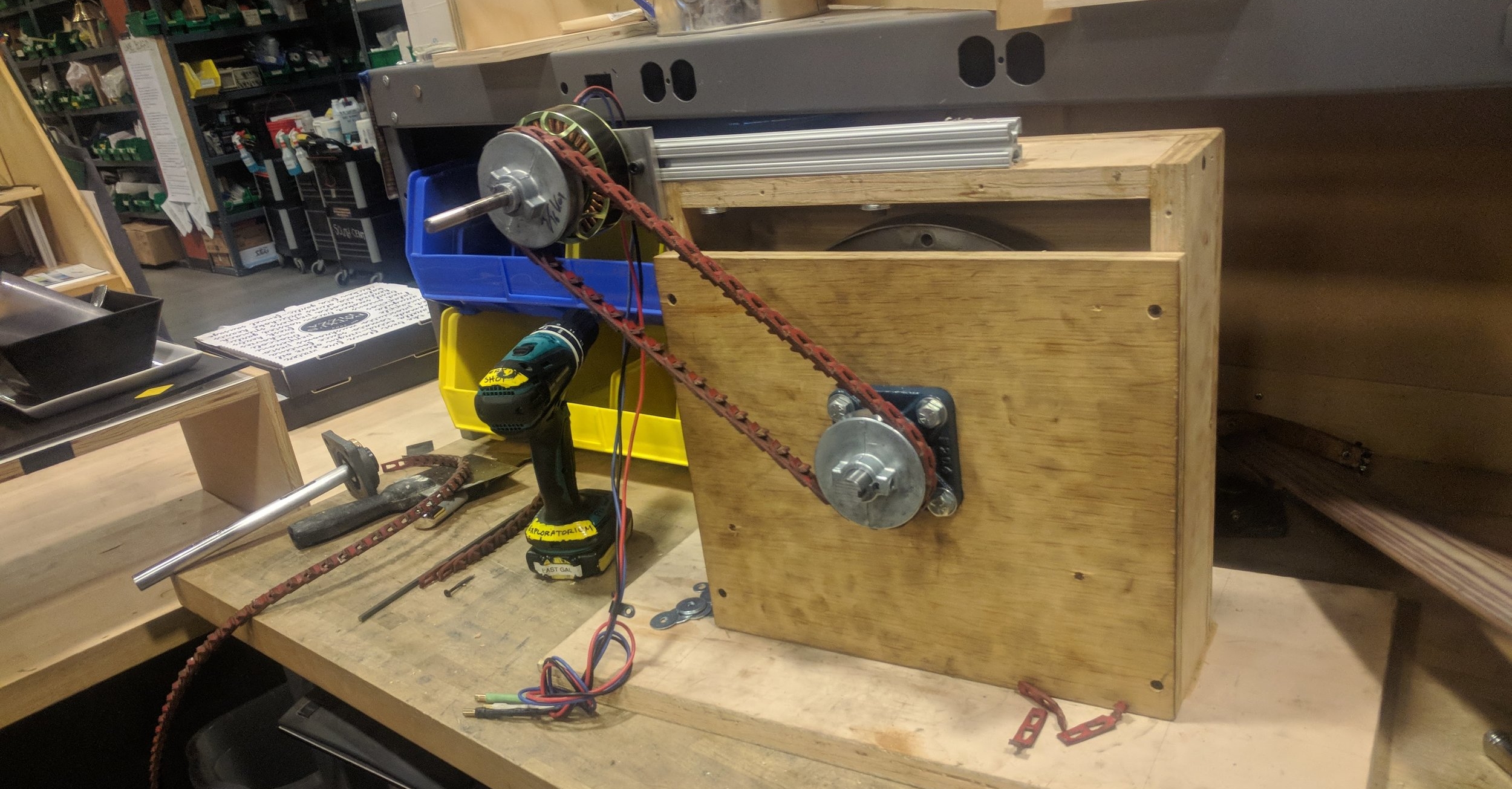

LAst Flywheel version

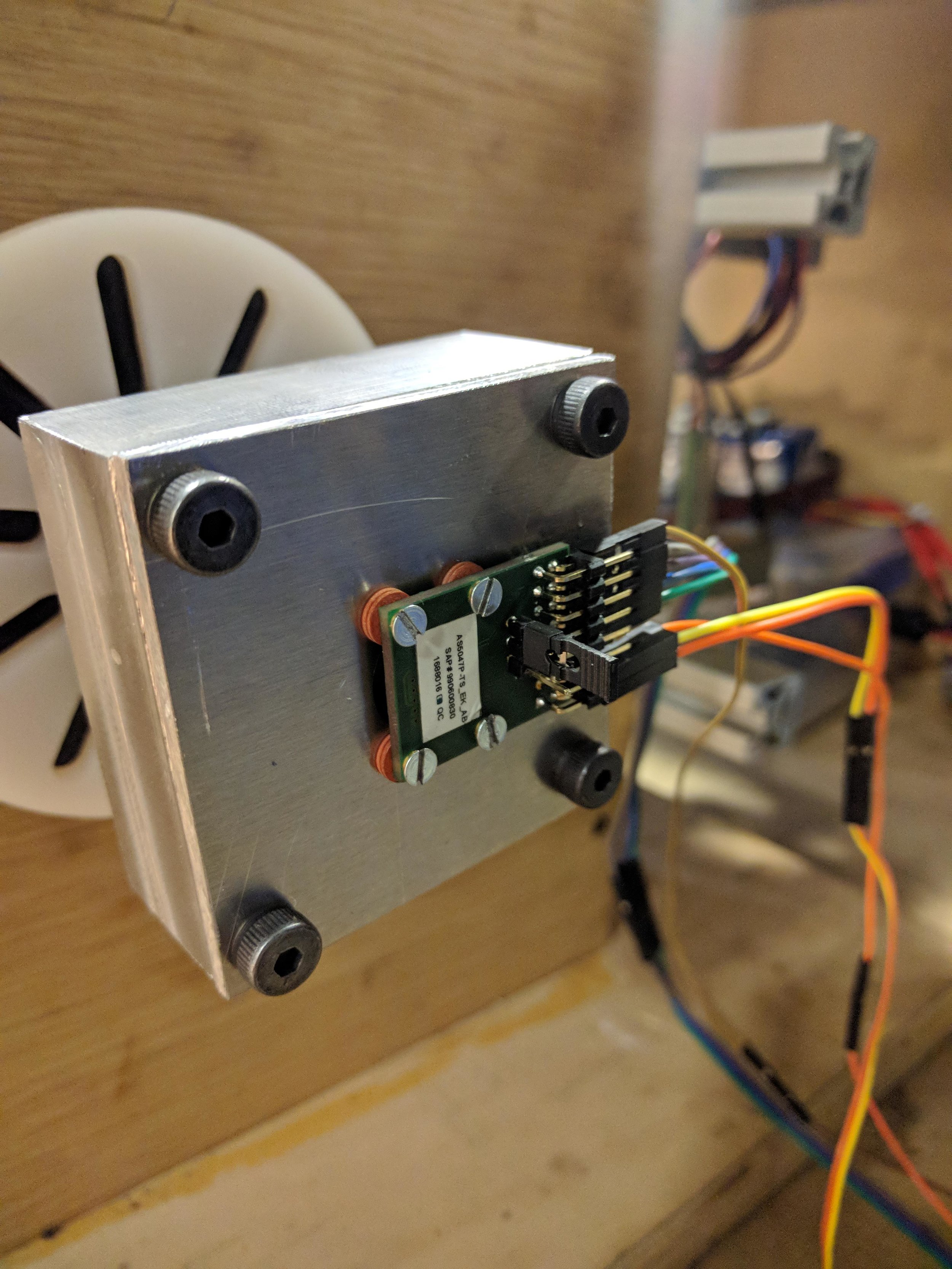

The last version of the flywheel dyno had a Teensy 3.5 running at 120Mhz. It was measuring 13 bit resolution (bi directional) current and voltage readings with 32 sample averaging, extra long sample and conversion times (to allow the cleanest ADC readings), 14 bit absolute angle encoder (16,384 discrete angles per revolution) with customized SPI interface library, and custom machined highly concentric sensor and magnet mounts to get the least non-linearity from the RPM sensor.

Unfortunately, the belt drive meant it detects the resonant losses in the belt to the flywheel, and well as whatever loss is intrinsic to the bearings and belt. :-/ The losses seemed to be non-linear, and frequency dependant, so the data wasn’t very useful.

I decided that i wanted to pursue a different direction. I wanted steady-state solution. I wanted cleaner data. I didn’t want a flywheel that had to be matched to the motor, or gearing to match the motor to the flywheel.

I decided to make a motor -generator dyno from what i’d learned from this dyno. Check that project out here , and notice how much better the graphs are. Repeatability is much higher, it’s easier to use, safer, has less intrinsic loss, can be used for steady state measurements, measures torque directly and etc.